tear test plastic film|tear resistance of plastic film : manufacture A quick video showing Universal Grip's scissor grips performing a tear test on plastic film using the Graves Tear Method. .more. An autoclave can be defined as an instrument used to clean any equipment and keep germs and bacteria-free. It is used in Laboratories, data centers, research centers, pharmaceuticals giants, educational institutes, .

{plog:ftitle_list}

Autoclavable ultralight and with balanced body offers greatest comfort for extended pipetting periods. Contoured and ergonomic body shape that fits perfectly to all hand sizes. Featured with a universal cone for standard .

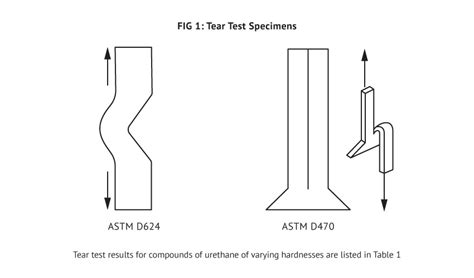

Scope. 1.1 This test method 2 covers the determination of the tear resistance of . A quick video showing Universal Grip's scissor grips performing a tear test on plastic film using the Graves Tear Method. .more. Scope. 1.1 This test method 2 covers the determination of the tear resistance of flexible plastic film and sheeting at very low rates of loading, 51 mm (2 in.)/min. and is designed to measure the force to initiate tearing.

A quick video showing Universal Grip's scissor grips performing a tear test on plastic film using the Graves Tear Method. .more.ISO 6383-1:2015 specifies a method of determining the tear resistance of plastic film or sheet less than 1 mm thick, in the form of standard trouser-shaped test specimens, tested under defined conditions of pre-treatment, temperature, humidity, and speed of testing.This part of ISO 6383 specifies a method of determining the tear resistance of plastic film or sheet less than 1 mm thick, in the form of standard trouser-shaped test specimens, tested under defined

One way to measure tear resistance is through the Pendulum Method or Elmendorf Tear Test, as defined by ASTM D1922. The Elmendorf Tear Test is a simple and reliable way to measure the force required to propagate a slit in a plastic film a .ASTM D1004 measures the tear resistance of flexible plastic film and sheeting. Raw materials manufacturers are constantly challenged to identify the ideal formula that minimizes material cost and waste while retaining the necessary strength.

5.1 Tear resistance of plastic film or sheeting is a complex function of its ultimate resistance to rupture. The specimen geometry and speed of testing in this test method are controlled to produce tearing in a small area of stress concentration at rates far belowASTM D1004 is a test method that determines the tear strength of flexible plastic film and sheeting at very low rates of loading using a constant-rate-of crosshead-movement type tensile testing machine. A physical model of one of the principal end-use tests of film manufactured from linear low-density and low-density PE resins, the Elmendorf tear test (ASTM D1922, ISO 6383-2), is described.

tear resistance test method

ASTM D1004 is a standard test method for the determination of tearing resistance of plastic film and sheeting. It gauges the force required to detach a specimen from its backing material by pulling it until it tears. Scope. 1.1 This test method 2 covers the determination of the tear resistance of flexible plastic film and sheeting at very low rates of loading, 51 mm (2 in.)/min. and is designed to measure the force to initiate tearing. A quick video showing Universal Grip's scissor grips performing a tear test on plastic film using the Graves Tear Method. .more.ISO 6383-1:2015 specifies a method of determining the tear resistance of plastic film or sheet less than 1 mm thick, in the form of standard trouser-shaped test specimens, tested under defined conditions of pre-treatment, temperature, humidity, and speed of testing.

This part of ISO 6383 specifies a method of determining the tear resistance of plastic film or sheet less than 1 mm thick, in the form of standard trouser-shaped test specimens, tested under defined One way to measure tear resistance is through the Pendulum Method or Elmendorf Tear Test, as defined by ASTM D1922. The Elmendorf Tear Test is a simple and reliable way to measure the force required to propagate a slit in a plastic film a .

ASTM D1004 measures the tear resistance of flexible plastic film and sheeting. Raw materials manufacturers are constantly challenged to identify the ideal formula that minimizes material cost and waste while retaining the necessary strength.

5.1 Tear resistance of plastic film or sheeting is a complex function of its ultimate resistance to rupture. The specimen geometry and speed of testing in this test method are controlled to produce tearing in a small area of stress concentration at rates far belowASTM D1004 is a test method that determines the tear strength of flexible plastic film and sheeting at very low rates of loading using a constant-rate-of crosshead-movement type tensile testing machine. A physical model of one of the principal end-use tests of film manufactured from linear low-density and low-density PE resins, the Elmendorf tear test (ASTM D1922, ISO 6383-2), is described.

tear resistance test material

test for hamstring tear

test for knee meniscus tear

It describes the working process where steam is generated and raises the temperature and pressure to 121.5°C for 15-30 minutes to effectively sterilize materials. .

tear test plastic film|tear resistance of plastic film